Best 3D Printing Software

Best 3d printing software are Meshlabs, Catia, Scupteo, and OnShape. Best 3D printing software will help you understand and design different types of 3D shapes in real-time

Connect With Your Personal Advisor

List of 20 Best 3D Printing Software

Emergents | 2023

Tinkercad is one of the best software for 3D printing for making simple 3D layouts and apps, which is used for designers, professors, architects, doctors, and children. Simple to create a design as per the user's mind. It offers characteristics, i.e., different shapes available, grouping, and updated 3d models. Read Tinkercad Reviews

Starting Price: Available on Request

High Performer | 2023

Software by RS Components

DesignSpark Mechanical is a fully featured 3D printer designs software designed to serve SMEs. DesignSpark Mechanical provides end-to-end solutions designed for Windows. In addition, this online 3D Design system offers Data Import / Export, For Printing, 2D Drawing, and Materials, For Manufacturers' bills in one place. Learn more about DesignSpark Mechanical

Starting Price: Available on Request

Emergents | 2023

FreeCAD is a fully featured CAD Software designed to serve Enterprises, Agencies. FreeCAD provides end-to-end solutions designed for Web App. This online CAD system offers Annotations, Data Import / Export, For Architects, For Manufacturers, Simulation at one place. Learn more about FreeCAD

Starting Price: Available on Request

Emergents | 2023

3D Slash is a computer-aided 3D printing software. It has a nice user interface for the game, imports designs from the web, and remixes and prints them. Include modules, i.e., modern tools for precise work, fast technology, and online and offline synchronized applications. Trusted by lots of users to acquire the talent. Learn more about 3D Slash

Starting Price: Available on Request

Emergents | 2023

Fusion 360 is a fully featured Collaboration Software designed to serve Enterprises, Startups. Fusion 360 provides end-to-end solutions designed for Web App. This online Collaboration system offers Project Management, Task Management, Version Control at one place. Read Fusion 360 Reviews

Starting Price: Available on Request

Recent Review

"Fusion 360 is Great" - Rolins Macwan

| Pros | Cons |

|---|---|

|

Fusion 360 is user friendly and give very great experience. This software is not need higher knowledge to use it. Even beginner also use. |

Rendering should be improve. |

Contenders | 2023

Onshape is the best 3D printer software that combines CAD and data management tools to contour the designing process. It permits users to assess and update knowledge instantly while not having to leave the platform. With the help of its integrated data management tools, engineers can give more time to the designing process. Learn more about Onshape

Starting Price: Available on Request

Siemens enables you to build foremost products with the help of the 3D printing software. It provides users with a transparent image of the support material required for a part. Users are allowed to visualize, identify, and isolate elements that may create problems for 3D printing, and resolve problems in early stage within the designing method. Learn more about Siemens NX

Starting Price: Available on Request

Category Champions | 2023

Ultimaker Cura is a fully featured 3D printing software designed to serve Agencies, Enterprises. Ultimaker Cura provides end-to-end solutions. This online 3D Design System offers 3D printing, CAD integration, and 3D Modeling in one place. Read Ultimaker Cura Reviews

Starting Price: Available on Request

Recent Review

"Ultimaker Cura review" - Fanuel Makokha

| Pros | Cons |

|---|---|

|

The easy of use and a variety of useful features that aid in 3D printing. |

The process of costing a 3D print using the software only focuses on the length of filament used instead of factoring in the electrical power consumption by the printer and labour |

Emergents | 2023

Meshmixer is the best design software for 3D printing, which helps you work better with triangle meshes. Its 3d software is a complete package with features such as drag-and-drop mesh mixing, 3D sculpting, hollowing, advanced selection tools, automatic printing, and much more. Learn more about Meshmixer

Starting Price: Available on Request

Meshlab is a software used for 3D printing that is most fitted for processing and editing 3D meshes. Users can use all its functions to give texture, edit, render, and convert into meshes. Moreover, you may slice and prepare the design for 3D printing. Learn more about Meshlab

Starting Price: Available on Request

Emergents | 2023

Simplify3D is one of the best 3D printer programs designed for designers, engineers, and manufacturers to create simulations, customize designs, and manage numerous printers. In addition, this best 3D printing software supports print management, queue management, and multi-printer management. Learn more about Simplify3D

Starting Price: Starting Price: $149 Per Month

Sculpteo is a software for 3D printing that allows digital sculpting to develop amazing 3D models. You can form 3D models by shaping any mesh through different brush strokes. The method appears similar to shaping a lump of clay in real time. Learn more about Sculpteo

Starting Price: Available on Request

Category Champions | 2023

SolidWorks is a 3d design software that helps to increase productivity by providing you with CAD solutions. It helps you through the product development process by providing you with tools for 3d designing, simulation, product data management and technical communication. This 3d modeling software is simple and easy to use for users. Read SolidWorks Reviews

Starting Price: Available on Request

Recent Review

"SolidWorks : My Personal Favourite" - AAKIF SHAIKH

| Pros | Cons |

|---|---|

|

With SolidWorks designing and simulation becomes a piece of cake, it provides a step-by-step procedure for doing any simulation study and gives the results as par real time scenarios. With a well built design tool library, I can import standard parts like gears, nuts, bolts, washers, screws, etc directly into my design interface which saves a lot of time and improves my productivity. I can also see my live simulation results in the animation wizard provided by SolidWorks. |

The meshing feature is not as advance as compared to Ansys, I can't do manual meshing of the surfaces if I wanted to study localized deformations in parts. The software sometimes lags while doing any complex analysis, hence need improvements in this area. |

|

Simplicity of User interface anyone can use Solid Works without training, one 4 to 5 hours of training required to understand upto 70% software basics. I am using Solid Works for 3D modelling and 2D detailing of solid components used in heavy equipment engineering. Also Inbuilt standard sizes of L angels and extruded bars are moreover helpful in Solidworks. 360degrees of viewing angles. Ability to view and create 2D and 3D file. Can export 3D pdf as well. Import almost all types of cad files. CAD library given in Solidworks is really helpful for designers. |

Solidworks is useful for sheet metal parts and solid geometry designing, but using it for plastic components is sometimes hectic for me it doesn't give freedom like catia for 3d modelling of plastic components this i dislikes. |

Contenders | 2023

MakePrintable is a fully featured software used for 3D printing designed to serve SMEs, Enterprises. MakePrintable provides end-to-end solutions designed for Macintosh. This online CAD system offers in one place. Learn more about MakePrintable

Starting Price: Available on Request

Contenders | 2023

SelfCAD is a 3D printer designs software designed for beginners and experts in 3D modeling. It offers various features and tools to create 3D models and designs. It also comes with its online 3D slicer for slicing designs. Read SelfCAD Reviews

Starting Price: Starting Price: $4.99 Per Month

Recent Review

"SelfCAD-Best 3D software for beginners" - Sammy Ekaran

Category Champions | 2023

AutoCAD Electrical is a fully featured Designing Software designed to serve Enterprises, Startups. AutoCAD Electrical provides end-to-end solutions designed for Windows. This online Designing system offers PLC Tools, Document Generation, Reusable Designs, CAD Tools, Electrical Parts Catalog at one place. Read AutoCAD Electrical Reviews

Starting Price: Available on Request

Recent Review

"AutoCAD Electrical" - Mohd Aurangzeb

| Pros | Cons |

|---|---|

|

It is very useful for making different Electrical Layout |

There is need some more automation. |

|

AutoCAD allows us to create 2D and 3D designs much more easily. Since there is a layering technique, we can create in a really intelligent way. |

Unfortunately, this program does not allow us to easily snap lines while creating 3D designs. |

Maya is a fully featured Content Marketing Software designed to serve Startups, SMEs. Maya provides end-to-end solutions designed for Windows. This online Content Marketing system offers Audience Targeting, Conversion Tracking, Distribution Management, Editorial Calendar, Publish Scheduling at one place. Read Maya Reviews

Starting Price: Available on Request

Recent Review

"Compact software" - sayan dutta

| Pros | Cons |

|---|---|

|

its modelling and texturing tools.easy to use .also its animation tools are mind blowing.easy to understand and take your creative mind to next level |

the rigging and fx part sbould be improved .its ok but you can make more userfriendly |

Modo 3D Design is 3d modeling software that helps you to get creative results.This 3d software includes modules that help you in painting, sculpting, shading, animation, and much more. It has got a user-friendly interface and has become the preferred choice for many users. Read Modo 3D Modeling Reviews

Starting Price: Available on Request

A dynamic additive 3D printing software Eiger offered by Markforged. Permits users to 3D print any part on-demand. The user needs to load the part created on the CAD program as an STL file, and from their user can also manage and catalog their files. Learn more about Eiger

Starting Price: Available on Request

GrabCAD is the best 3D printing software that enables organizations to streamline their CAD-to-Print advancement processes. The software system makes 3D printing simple and manageable and provides quality components quickly. In addition, it reduces the efforts and time needed for 3D printing and keeps track of new requests. Learn more about GrabCAD

Starting Price: Available on Request

Until 31st Mar 2023

What is 3D Printing Software?

Every 3D print begins as a 3D model that is generated with the help of modeling programs. These modeling programs are browser-based 3D design applications. The software is like a building block for users who want to develop 3D models by using a set of basic shapes. It lets users access the library of millions of shapes and lets them find shapes that suit them to further manipulate it.

3D printing is sometimes also referred to as additive manufacturing. The software offers feature-rich tools for sculpting, rendering, video editing, animation, simulation, and motion tracking. 3D printing software encompasses a wide variety of products such as slicers, computer-aided manufacturing (CAM), computer-aided design (CAD), design automation, and others.

CAD covers the part where designing, scaling, and features take part, along with a few CAD software such as Autodesk Inventor, Siemens NX, etc. The result of this phase would fetch a 3D digital model. In comparison, CAM takes care of the preparation and manufacturing process. The result of this phase would fetch the real 3D object.

The best 3D printing software should be able to deliver the following things:

-

Flexibility for a variety of workflows

-

A reliable process that delivers accurate results with minimal configuration

-

Optimization of print duration, part strength, and material used

-

Support for multi extrusion printers

-

Functional scalability

Role of software in 3D printing workflow no matter what 3D printer user may use is an essential step is preparing a 3D model file first using slicing software (also called slicer). The basic function of the slicer is to slice the 3D file into horizontal layers to make it suitable for the further printing process. Besides this, a slicer can be considered a toolkit capable of performing complex functions to prepare a 3D model for fabrication.

Why Use 3D Printing Software?

Here are the top benefits of the best 3D printing software that customers must keep in mind while buying it:

1. Less Turnaround Time

Rapid prototyping is the primary benefit of 3D printing software. It enables companies to meet consumer demands in less time. With rapid prototyping, it becomes possible to test the designs created through CAD software and eliminate the errors without actual loss. This takes not more than a couple of days. However, the traditional method takes a couple of weeks.

2. Cost Saving

3D printing is the most cost-effective process. It does not require costly custom-made tools and equipment for its working. Companies can easily replace the 3D printing tools without wasting much time and cost.

3. Freedom in Designing

With 3D printing, it becomes possible to create complex geometry easily. This will let you simplify your designs and add more creativity to them. This easy-to-use tool can be used by anyone, even with less experience in CAD. You can create and customize unique designs as per your requirement.

4. Reduced Waste

3D printing uses only the required amount of material for the manufacturing process. Unlike the traditional methods that use large amounts of materials and cut away the major portion of it as waste during the actual process. The 3D printing process reduces the waste and saves on the cost of the material.

5. Competitive Advantage

With very less manufacturer to consumer time, 3D printing offers a competitive advantage to the companies. The companies enhance their product and make changes in the product based on the feedback collected from the potential customers. This lets them in saving the time required for future changes in products and cuts down the waste.

6. High Quality and Consistency

3D printing gives high-quality products to companies with its step-by-step designing method. This shows the designers how the 3D printing process is progressing and lets them make changes in the process at that particular step itself. Traditional methods, on the other hand, may result in low-quality designs and poor prototypes.

In manufacturing processes, usually, a bunch of products is manufactured at a time. With the traditional method, there are high chances that the products manufactured can turn defective as well as inconsistent at the same time. 3D printing solves this problem. Here parts are manufactured in series and are monitored such that all the errors are eliminated, thereby increasing the consistency of the process.

7. Great Accessibility and Environment Friendly

3D printing does not require high skills and huge experience. Hence, it can be used by a broader range of individuals. Implementing this process is quite easy and cost-friendly. Thus, smaller organizations can also implement it. It becomes more accessible with the automation in its process and requires less monitoring.

3D printing has a low impact on the environment as it does not require high-level energy consumption. It also creates minimal waste, and the best part is the materials are mostly recyclable.

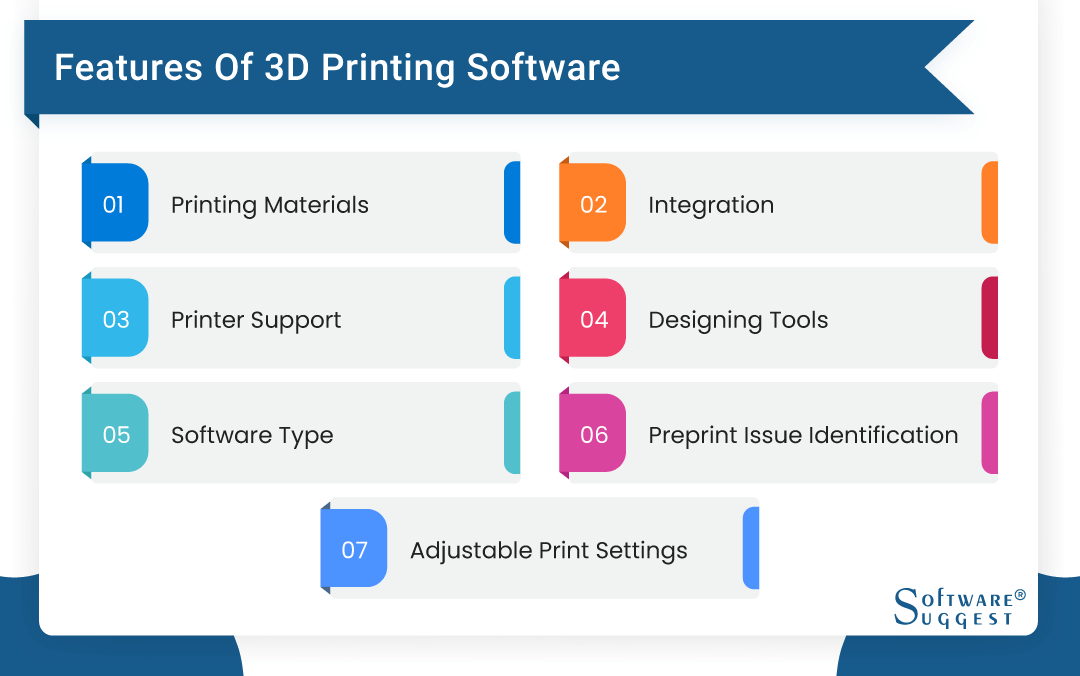

Features of 3D Printing Software

1. Printing Materials

The fast and efficient 3D printing software uses various materials for 3D printing. These materials come in different temperature ranges. Different materials include nylon, polycarbonate, PVA, PLA, and the list continues.

2. Integration

The base of a 3D print job is formed of 3D models. 3D printers should be able to communicate with these tools so that data from a 3D modeling software can be accessed and converted into a form that the 3D printer recognizes.

3. Printer Support

3D printing tools should have good compatibility with the range of 3D printers. It is especially important to make sure that the 3D printing software you choose is compatible with the 3D printer you will be using.

4. Designing Tools

The designing tools comprise drawing tools, 3D modeling, visualizing, rendering, and editing tools. With access to these tools, you can edit the design by using the 3D printing software.

5. Software Type

This feature gives you the option of software type. The 3D printing software comes in two software types: either you can opt for a cloud-based platform or you can download the application and make the best use of it.

6. Preprint Issue Identification

By running a preprint model, you can get information, including real speeds and series. This ensures you go ahead with the print job only when you are certain that it will be satisfactory.

7. Adjustable Print Settings

With the 3D printing software, you can get variable print settings that can be used for distinct sections of your print. This simple-to-understand setting can be done with a couple of clicks on the software.

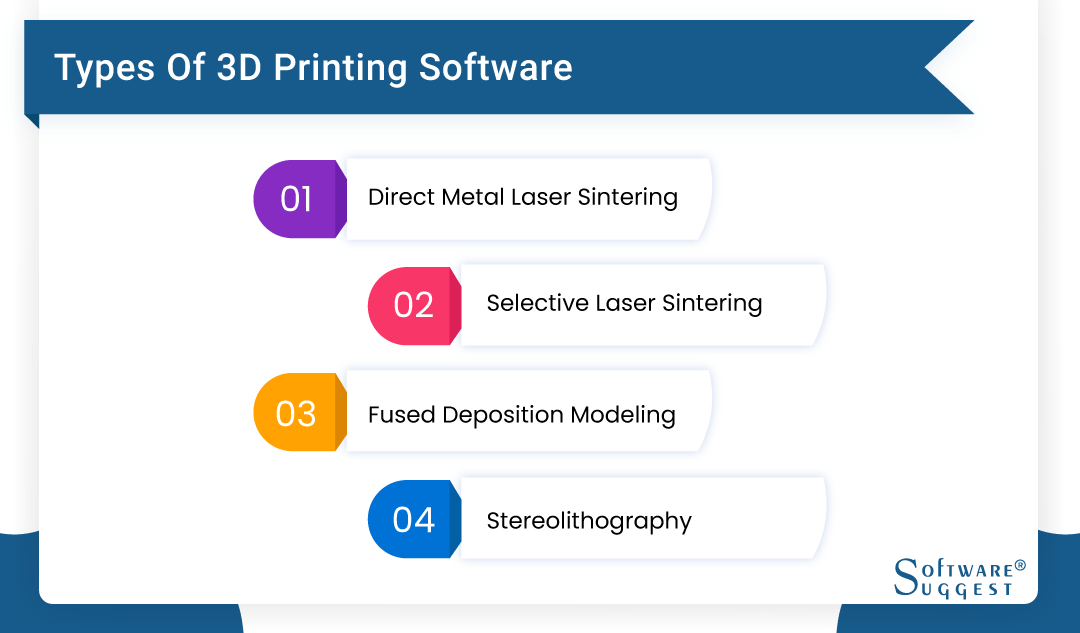

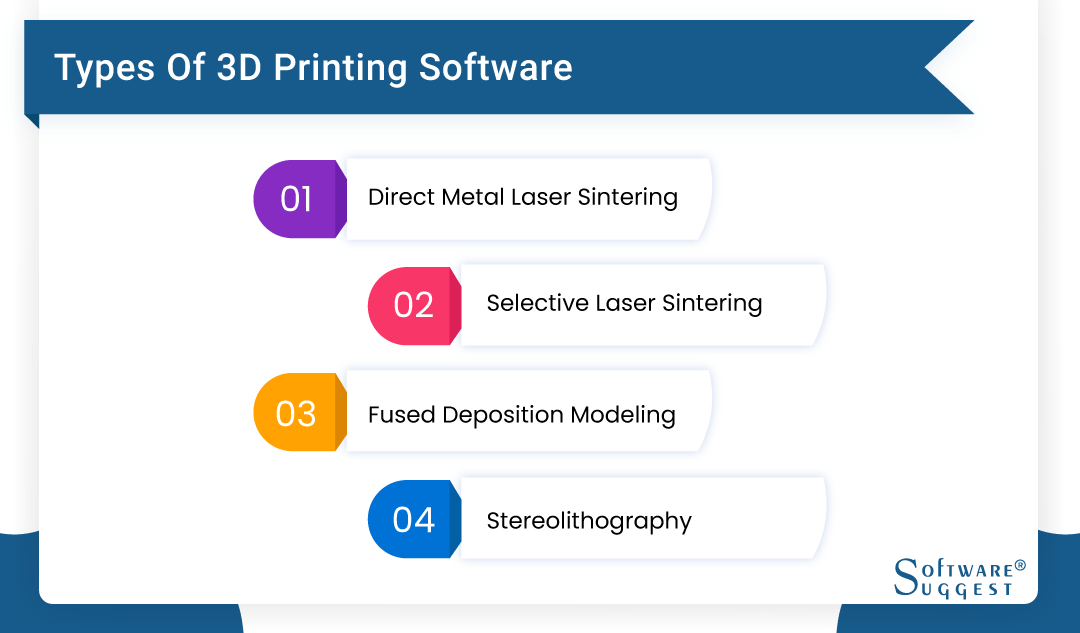

Types of 3D Printing Software

There are various 3D printing solutions developed to build real-life 3D structures and objects. All 3D printing systems have the same result. However, some 3D printing software solutions are prevalent nowadays, and others have fallen by the wayside due to changes in the ways they print out the objects. Below find a list of the most common 3D printer tool used in 3D printing today - stereolithography (SLA), fused deposition modeling (FDM), selective laser sintering (SLS), direct metal laser sintering (DMLS), polyjet or multijet printing (MJP), Inkjet printing, electron beam melting (EBM), laser metal deposition (LMD), laminated object manufacturing (LOM), and digital light processing (DLP). DMLS, SLS, and FDM are the most established and the best 3D printing software widely used in 3D printing technology.

1. Direct Metal Laser Sintering (DMLS)

DMLS is also called direct metal laser melting (DMLM). This method is similar to that of the SLS-based 3D printers; the only difference lies in the materials used. DMLS is used for building metal parts, and SLS is used for the printing of plastic-based parts. DMLS is used for rapid prototyping and mass production of metal parts such as Inconel, aluminum, stainless steel, and titanium. DMLS-based 3D printing solution is ideal for developing oil and gas components, custom medical guides, consolidated aerospace parts, and difficult functional prototypes.

2. Selective Laser Sintering (SLS)

SLS is a new technology mainly used for rapid prototyping and low-volume production of component parts. The SLS-based 3D printer uses a high-power laser source to sinter small particles of polymer powdered material (nylon or polyamide) to create a solid structure. The common material used for the SLS process is nylon, a lightweight, strong, and flexible engineering thermoplastic that has excellent mechanical properties.

3. Fused Deposition Modeling (FDM)

Fused deposition modeling is also known as fused filament fabrication (FFF), Plastic jet printing (PJP), or filament freeform fabrication. FDM is the most common and widely used printing solution at the consumer level. FDM 3D printing process uses a continuous filament of a thermoplastic material.

4. Stereolithography (SLA)

Stereolithography is also known as stereolithography apparatus, optical fabrication, photo-solidification, or resin printing. Stereolithography is the oldest, most popular, and best 3D printing software used by professionals. SLA uses lasers and mirrors to print out an object layer by layer. SLA 3D printing technology is used for lightweight concept models, prototypes, anatomical models, form and fit studies, architectural models, urethane casting patterns, investment casting patterns, and production parts, as this technology provides a high-quality surface finish.

SLA resin 3D printers could deliver accurate, isotropic, and watertight prototypes and parts with fine features and a smooth surface finish. This is a particularly good option for highly detailed prototypes that needs tight tolerances and smooth surfaces. SLA resin formulation offers a broad range of optical, mechanical, and thermal properties to suit those of standard, engineering, and industrial thermoplastics.

The major companies offering SLA-based 3D printers and services are 3D Systems, Form Labs, Autodesk, and 3D Ceram. SLA-based 3D printer systems are widely used in engineering, product design, short-run manufacturing, dentistry, jewelry prototyping and casting, model making, and education industries.

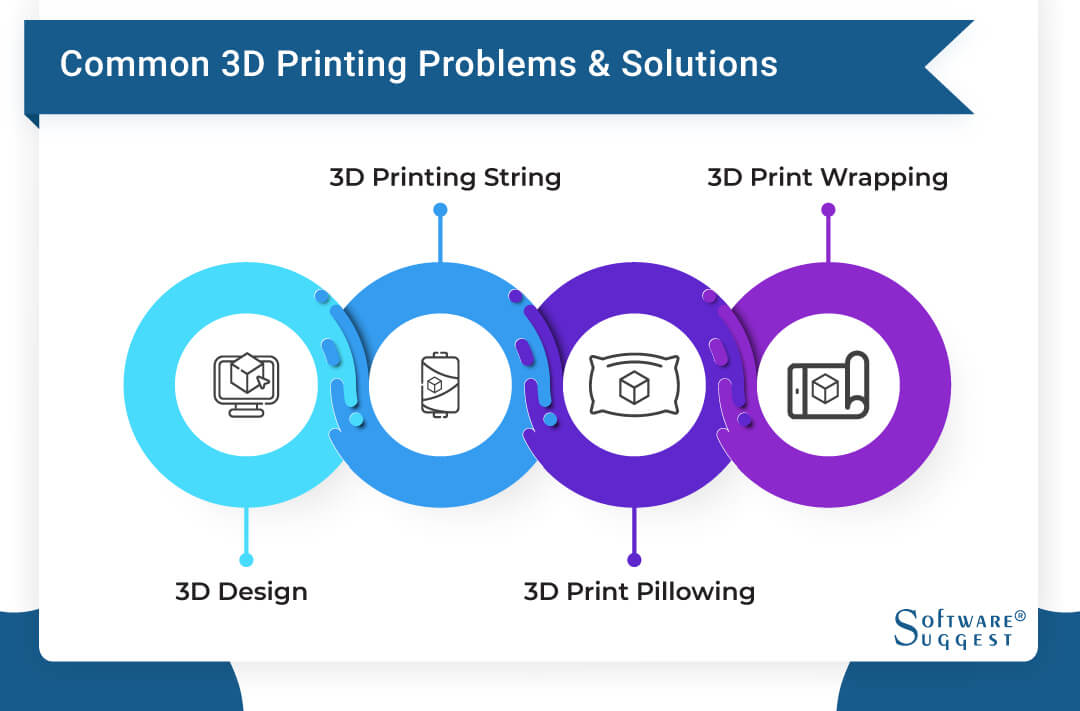

Common 3D Printing Problems and Solutions

1. 3D Design

Since the 3D industry is evolving rapidly now and then, new kinds of materials are introduced in the industry, but the user needs to understand what kind of material will suit them the best. As 3D printing goals are different, one must know if they want solid or flexible output. Now, based on these goals, one needs to correctly choose their 3D design, or the output can be of totally different quality. Hence, it is suggested to carefully choose the right material and follow design guidelines as it will save a lot of money and time.

2. 3D Printing String

This is one of the most common problems faced by people using 3D printers. In this case, the melted plastic oozes out of the nozzle while printing the object. The oozed-out plastic solidifies, and it is difficult to get rid of it. Users can overcome this problem by enabling retraction. When we do this, the filament inside the nozzle is pulled back and stopped from moving. Also, increasing the retraction speed will decrease the chances of stringing.

3. 3D Print Wrapping:

This occurs when deposited material starts cooling during the printing process. Such untimely and uneven cooling causes the parts to deform, resulting in a defective object as output. To avoid this issue, heated print beds are used, due to which the time increases for the layers to cool down when it is deposited, saving filaments from wrapping. Another idea is to build surface adhesion; it will help with other filaments.

4. 3D Print Pillowing:

This occurs on the object that is printed with a 3D printer. The object has holes and deformities formed on its topmost layer. This occurs due to improper cooling as the top layer fails to get enough cool air. To overcome this, one must set a thick topmost layer and adjust cooling.

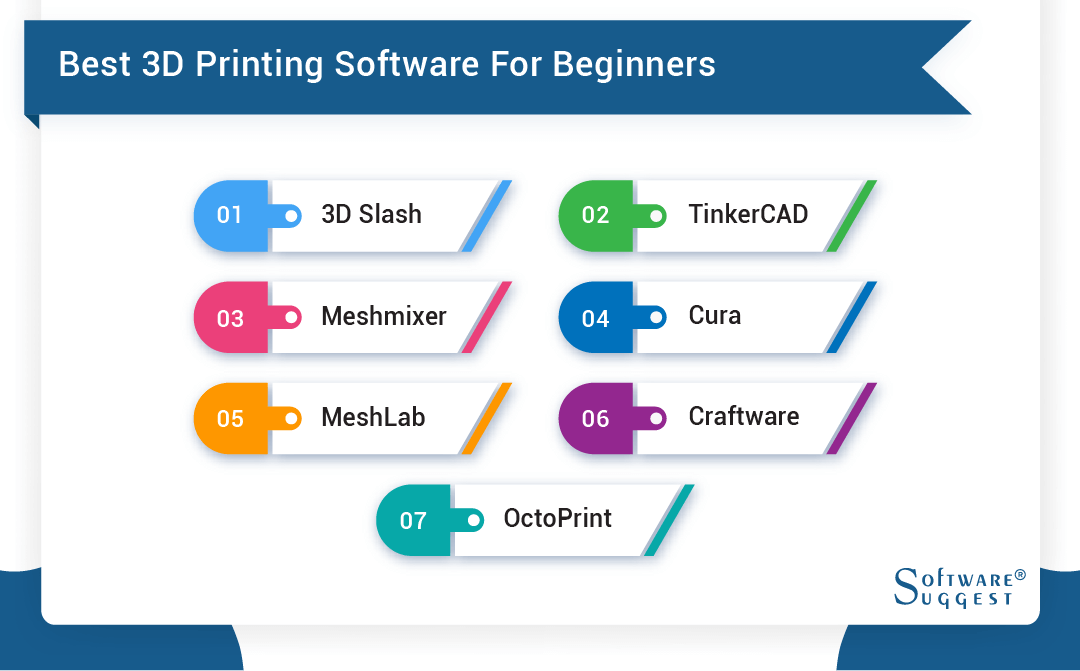

Best 3D Printing Software for Beginners

3D printing software has become one of the popular software in the industry. Every size of business is implementing this software. But selecting the best 3D printing software out of a number of options available can be a tedious task. Considering this, we have listed the top 3D printing software that beginners can implement.

1. 3D Slash

3D Slash is an open-source and easy-to-use 3D printing tool. Unlike other software, it is a logo and 3D text maker. With its simple features, you can quickly make the best use of it as a beginner.

2. TinkerCAD

TinkerCAD is CAD software that can be used online for 3D printing. Once an account is created, you get access to all the apps that you need to start your 3D printing process.

3. Meshmixer

This is a free tool with numerous features that can edit, fix, and sculpt your 3D design, which can always be a great choice for beginners.

4. Cura

Cura is the user-friendly slicing software for 3D Printers. It exports files that can be easily understood by 3D printers along with its support for Windows, Mac, and Linux.

5. MeshLab

MeshLab is free software that can transform 3D meshes. It is best used for 3D alignment, reconstruction and supports Android and iOS.

6. Craftware

This wonderful software designed by CraftUnique is a slicer software and supports CraftBot 3D printer. Any 3D printer accepting G-code can use it. With its simple UI, it becomes one of the best 3D printing software for beginners.

7. OctoPrint

OctoPrint is a robust and free 3D printing tool that comes with remote monitoring of designs and customizable UI. It is compatible with all the 3D printers and can be good for beginning your 3D printing.

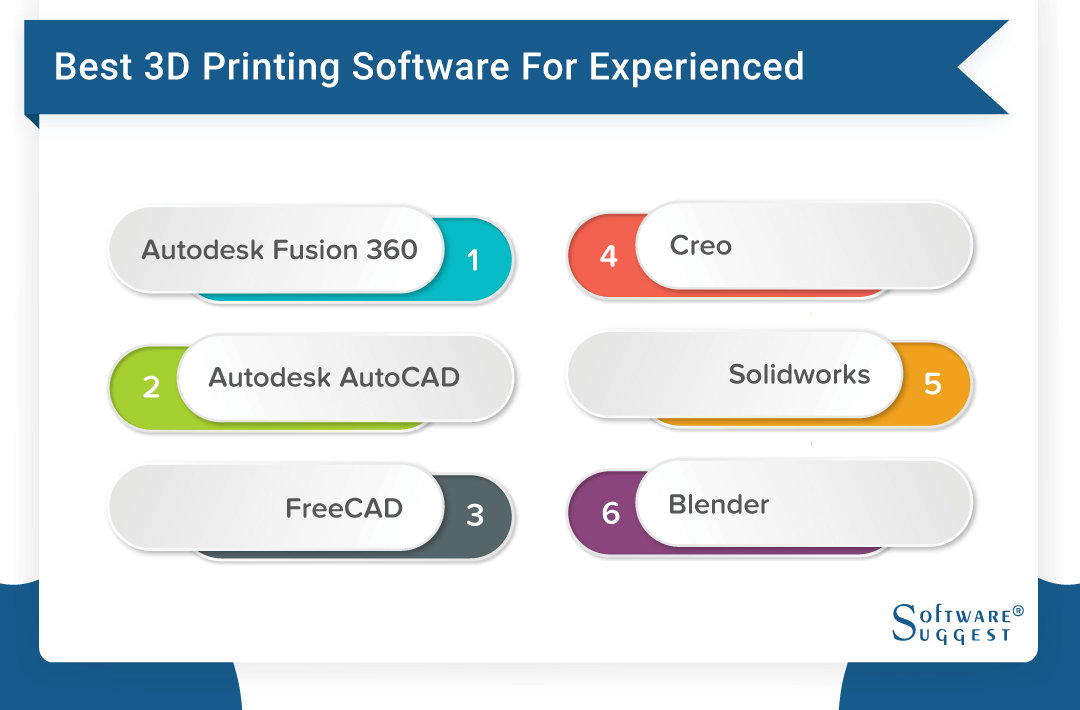

Best 3D Printing Software for Experienced

1. Autodesk Fusion 360

Autodesk Fusion 360 is a cutting-edge 3D printing software that provides cloud-based 3D CAM, CAD, and CAE functionalities for product development. The software integrates mechanical & industrial design, simulation, collaboration, and machining on one platform. It is a one-stop solution for all product design and development processes. Fusion 360 synchronizes bidirectional modifications from electronic designs using EAGLE interoperability. It uses cloud credits to develop and analyze multiple tests without the need for expensive hardware. Fusion 360 is used by product designers, mechanical and electrical engineers, and machinists.

2. Autodesk AutoCAD

AutoCAD is a very versatile and amazing 3D printing tool most suitable for professional users who have extensive experience in programming models. It has a lot of capabilities to create detailed 3D models. It can easily convert 3D models into STL files for an efficient 3D printing system. AutoCAD includes the latest edition of DWG file format for the effective drafting of files across various formats. The user can easily modify and create robust mechanical designs for a 3D printing solution.

3. FreeCAD

FreeCAD is an open-source 3D modeling tool that can be used for a wide array of applications such as architecture and mechanical engineering. It offers excellent capabilities to design real-life designs of any shape and size and provides related components to make 3D model editing easier and more efficient. You can use FreeCAD as an efficient 3D printing training tool.

4. Creo

Creo by Parametric Technology Corporation offers excellent capabilities to design, simulate, and print 3D models expeditiously through modeling, surfacing, finite element analysis, and tooling abilities. It is one of the best 3D printing software that has amazing functionalities such as motion, structural, and thermal, etc. Creo comes with the best topology optimization technologies and offers multiple tools to create stunning designs for designers.

5. Solidworks

Solidworks developed by Dassault Systemes offers a wide range of tools to efficiently design 3D models for industrial purposes. Solidworks software offers several detailed and unique features that allow 3D professionals to create innovative and reliable designs.

6. Blender

Blender is an open-source 3D animation and modeling software that is simple to use, configures quickly, and works efficiently. Blender provides supports to the 3D pipeline, modeling, animation, simulation, rendering, motion tracking, video editing, and game creation. Blender app offers a vast range of plug-ins for making different forms of templates, simulations, animations, etc.

The Setup Process of 3D Printing Software

For setting up 3D printing software, few things must be ensured.

3D printing requires a balance between slicing settings and material properties. A designer must work with these constraints to be able to create a proper digital model. The following must be taken into consideration during the setup process:

First, to install and configure the software, a few series of steps must be followed.

The 3D file (STL, OBJ, or 3MF), exported from CAD 3D modeling software to 3D printing software (also called slicer), comes into the picture. In the printer settings, adjust the depth and width (increase it), for example, from 220mm to 235mm.

Then need to put it on the virtual print bed. The toolbox will open where the dimension can be increased or decreased, or the object can be rotated.

-

Geometry: While giving an FFF print, geometry becomes more crucial because geometrically complex parts need adhesion structures or support material. These additional materials can be created with the help of slicer software.

-

Slicing Setting: There are two common settings here.

-

Overhangs and Support: Fused Filament Fabrication (FFF) printing is a bottom-up process, which means each layer is supported by a layer underneath it. Support material is used if an object has an extended part.

-

Adhesion: This is an important part as it gives the 3D object the support it requires. The most used method is called a brim – it prints an additional border.

-

Thickness: The thickness of the wall must be specified before printing; one must keep in mind that the wall thickness of the object must be greater than the nozzle being used in the printing process.

-

Layer Height: The thickness of each layer is known as layer height. Thicker layer height will reduce the resolution and the print time, whereas the thinner layer produces sharper resolution but extends the printing time.

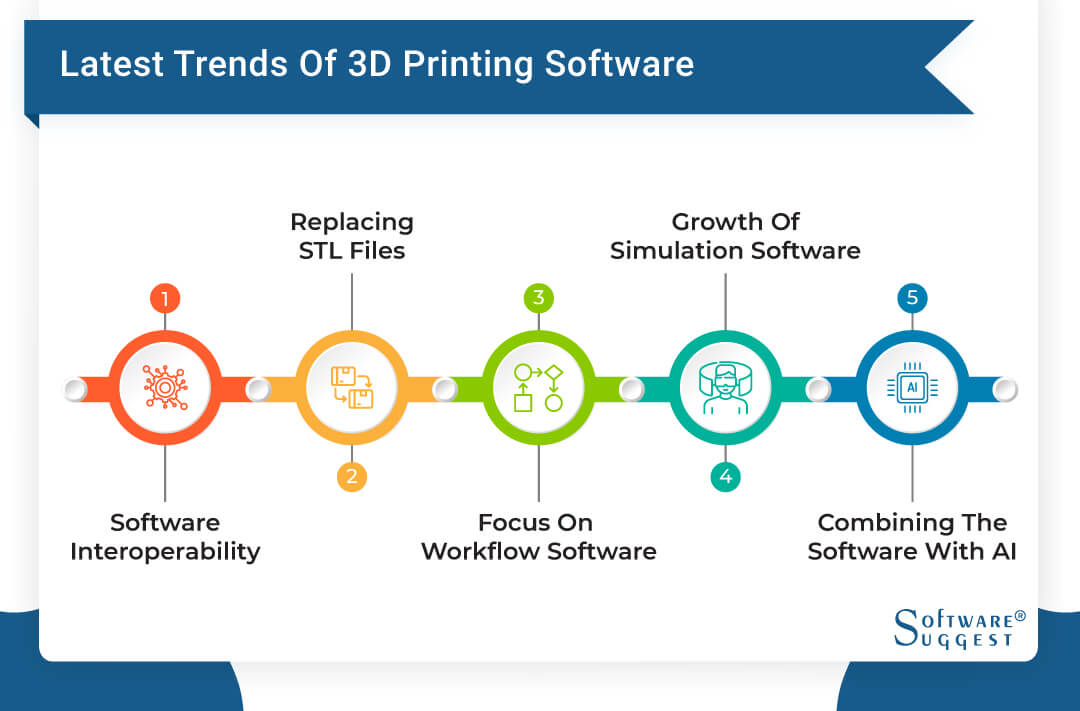

Latest Trends of 3D Printing Software

1. Software Interoperability

As we move toward a faster and easier design preparation workflow, we need greater software integration. Interoperability helps reduce the number of tools and steps and efforts needed in designing a model. Now, this is happening in multiple ways such as software integration, acquisition, or development of capabilities internally.

2. Replacing STL files

STL files were invented in the mid-1980s, which enabled CAD software to transit files to prints 3D objects. These STL files are a little difficult to use because they have many limitations such as unable to accurately define large and complex geometric shapes. The format does not specify color, texture, and many others. Hence, the introduction of 3MF, an open-source 3D file format, was quite a relief for users.

3. Focus on workflow software

Workflow management software has witnessed tremendous growth and helps overcome workflow inefficiencies.

4. Growth of simulation software

It is an excellent choice for minimizing the print failures that happen in later stages. It is used at the design stage to digitally reproduce how a material would behave during the printing process.

5. Combining the software with AI

This integration would further enhance the design and workflow process on the design front itself. AI gives engineers the option to explore unexpected design options.

Research Report of 3D Printing Software

Research report of 3D printing software market talks about market overview along with the in-depth study of how the market will grow in the near future. The 3D printing market is also segmented based on its offering, process, application, end-user, and geographical location.

Complete SWOT analysis of the 3D printing market is done for understanding its growth factors, restraints, opportunities, and challenges. The market is strategically analyzed, depending on its market trends and prospects. With the identification of newer opportunities in the market, companies can enhance their strategies and products for gaining a competitive advantage. Overall, the entire 3D printing market is studied, covering both demand and supply areas.

The supply side of the 3D printing market covers the market based on its offering, process, technology, and application. Offering includes a printer, material, software, and service. The process covers powder bed fusion, material extrusion, material jetting, binder jetting, sheet lamination, etc. Technology includes stereolithography, fused deposition modeling, selective laser sintering, inkjet printing, direct metal laser sintering, and multijet printing. The application includes prototyping, functional part manufacturing, and tooling. The demand side is analyzed based on end-users and regions. Various end-users comprise industrial, healthcare, consumer, automotive, education, jewelry, food, and many more. Geographical regions cover North America, Europe, APAC, and RoW.

The research report of 3D printing software includes a competitive landscape that provides a brief summary of the leading players in the 3D printing market. All the growth strategies of the organization are discussed in this part. The strategies are divided into Organic and Inorganic strategies, wherein organic covers product launches/developments and expansions and inorganic covers mergers/acquisitions, and partnerships/agreements/collaborations. In this section, companies are rated based on their technological expertise, product offering, market share contribution, target market, and mergers & acquisitions.

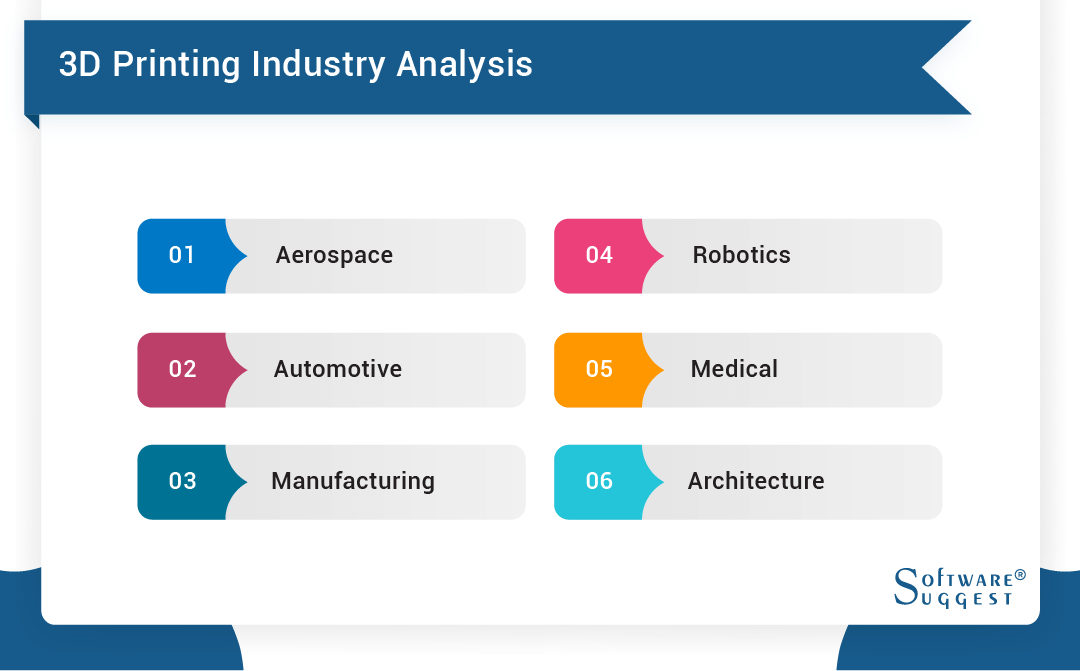

3D Printing Industry Analysis

The global 3D printing market size was valued at USD 13.78 billion in 2020 is expected to grow at the rate of CAGR of 21%. Following are the industries where 3D printing is widely used:

-

Aerospace: This industry expects the highest standards in part performance. The parts must be able to withstand high temperature and chemical resistance. Part failure often results in system failure, which is not an option.

-

Automotive: This is one industry that has been ahead in using additive manufacturing. For example, Audi has been using 3D printing for many years. The most common printed parts by automotive manufactures are cradles, fixtures, and prototypes, which are supposed to be stiff and durable.

-

Manufacturing: 3D printing is giving the manufacturing industry an opportunity to create customized low-volume tooling and fixtures at the traditional price.

-

Robotics: 3D printing is useful for making parts like grippers and sensor mounts, which are expensive to fabricate.

-

Medical: This industry has been using 3D printing in several ways possible for many years. For example, dentists use 3D scanners to get a 3D print of their patient’s jaw. Dentists produce 3D printed braces, aligners, dentures, and other things as well. Doctors and engineers had also developed knee replacements.

-

Architecture: From preparing a 3D model to an actual house, 3D printing is extremely useful for this industry. It gives architects a better opportunity to make their clients understand the space they are about to purchase.

FAQs of 3D Printing Software

• Flexibility with a wide range of workflows

• Ability to customize settings according to usage

• Ability to integrate with other software across the industry for a smooth workflow

• Scalability, so as to handle increasing volumes easily

• A centralized platform for various functions, even letting the user print a specific part of a product without having to order from elsewhere.

• Helping manage costs, including logistics, as all parts can be produced in one place.

• Reducing wastage by printing only those parts that are needed as the final output.